Diamond Seal Shower Glass Coatings

Why Do You Need Them? 5 Q&A’s to Find Out!

Protects Glass Surface & Corrosion Free

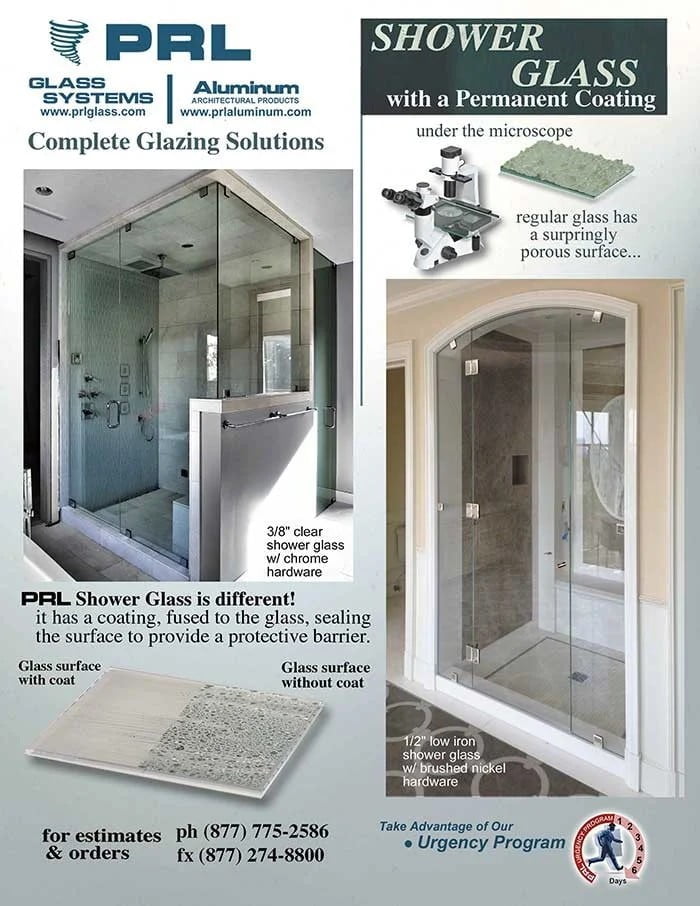

How Do Diamond Seal Shower Glass Coatings Work?

This shower glass coating seals the glass surface to create a protective barrier. Uncoated shower panels have a remarkably porous surface when viewed under a microscope. This develops areas where chemicals from household cleaners, soap build up, minerals and stains can deposit. But, when Diamond Seal shower glass coating is applied, it eliminates these porous areas and forms a barrier that guards against the damage harsh elements can leave behind.

Why Does This Shower Glass Make Cleaning Easier?

Diamond Seal coatings help reduce your cleaning time by sealing your shower glass surfaces. Ideal for swing door shower systems and sliders, this shower glass coating protects your enclosure’s panels from clouding and keeps shower glass shiny and brilliant for years to come. Resistant to water beads, fingerprints and smudging, Diamond Seal shower glass coating also makes maintenance simple for steam units and shower partitions.

Will My Clients Diamond Seal Shower Glass Panels Corrode Over Time?

No, these shower glass coatings are strong and durable. Whether your client is installing a standard or custom shower system, panels and shower doors treated with Diamond Seal won’t corrode over time. After accelerated exposure tests to heat and humidity in a typical bathroom, shower glass treated with these coatings showed no signs of corrosion. Perfect for residential and heavy commercial use, this Diamond Seal product will tolerate several shower and bath applications. Tests were performed in a 140˚ F bathroom with 95% relative humidity for 1,000 hours.

Reapplication & Shower Glass Types

Do I Need to Reapply This Shower Glass Coating or Use Special Glass-Handling Techniques?

No. Diamond Seal shower glass has a permanent coating that doesn’t require any special conditions. Unlike treatments applied to glass after fabrication, we fuse Diamond Seal coatings to the glass surface during manufacturing. This tempering process activates the permanent coating and not only eliminates the need for reapplication, but also eliminates the use of special glass-handling gloves or equipment. All Diamond Seal shower glass coatings come with a 10 year manufacturer warranty that covers the shower glass panels in our swing and sliding shower door enclosures.

What Shower Glass Types Can Diamond Seal Coatings Be Applied To?

This shower glass coating can be applied to all shower glass types we generate. Excellent for framed and frameless shower door units, you can have Diamond Seal coatings applied to everything from functional to decorative shower glass types. This includes clear tempered, low iron, textured and patterned shower glass as well as spandrel, glue chipped and sandblasted shower panels. All you have to do is request Diamond Seal shower glass coatings when you quote your shower systems.

Bid Diamond Seal Shower Glass Coatings with Us! We Answer Your Questions!

Get Diamond Seal shower glass coatings at PRL! Because we know informed customers are happy customers.

For Complete Panic Device Hardware Specifications, Estimates and Orders

Please Feel Free to Contact Us Directly

Toll Free (800) 433-7044

NEED COMPLETE SHOWER DOOR SYSTEMS FAST?

Shop at PRL Glass & Aluminum!

Need complete shower door systems fast? Shop at PRL! Our frameless hinge/pivot enclosures arrive in 48 hours when you specify standard shower units with tempered glass and hardware*. Shipped prefabricated and ready-to-install, our complete systems include all components. And these stand-alone shower enclosures arrive with all perimeter supports, headers and u-channels pre-cut with Read More...

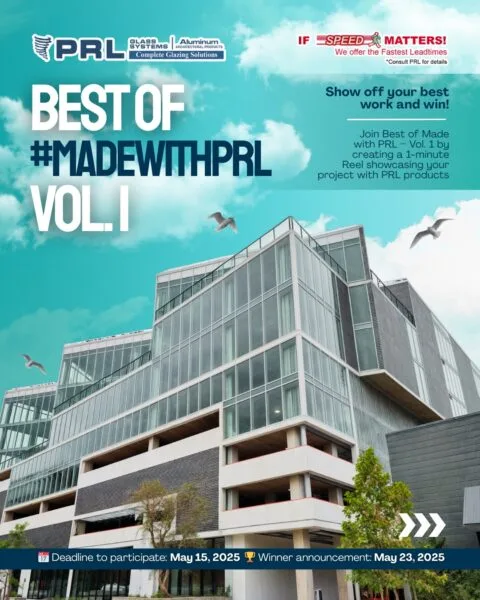

PRL’s CONTEST – Best of Made with PRL – Vol. 1

PRL’s CONTEST – Best of Made with PRL – Vol. 1

Prizes:

- 1st Place: iPad Pro – Powerful, Sleek, and perfect for content creation.

- 2nd place: iPad – More Storage for bigger ideas.

- 3rd Place: DJI Osmo Mobile Stabilizer – Smooth video content every time.

How to Participate:

- Create a Reel: Showcase your best project using PRL products.

- Explain it: In the Read More...